Industrial Piping Systems

From municipal waterworks to industrial intakes and discharges, our team has the experience and resources needed to handle projects of any size.

Our plumbers and pipe fitters provide service for multiple process piping systems. This includes glycol, thermal oil, steam, air, water, gas, refrigeration and condensate piping.

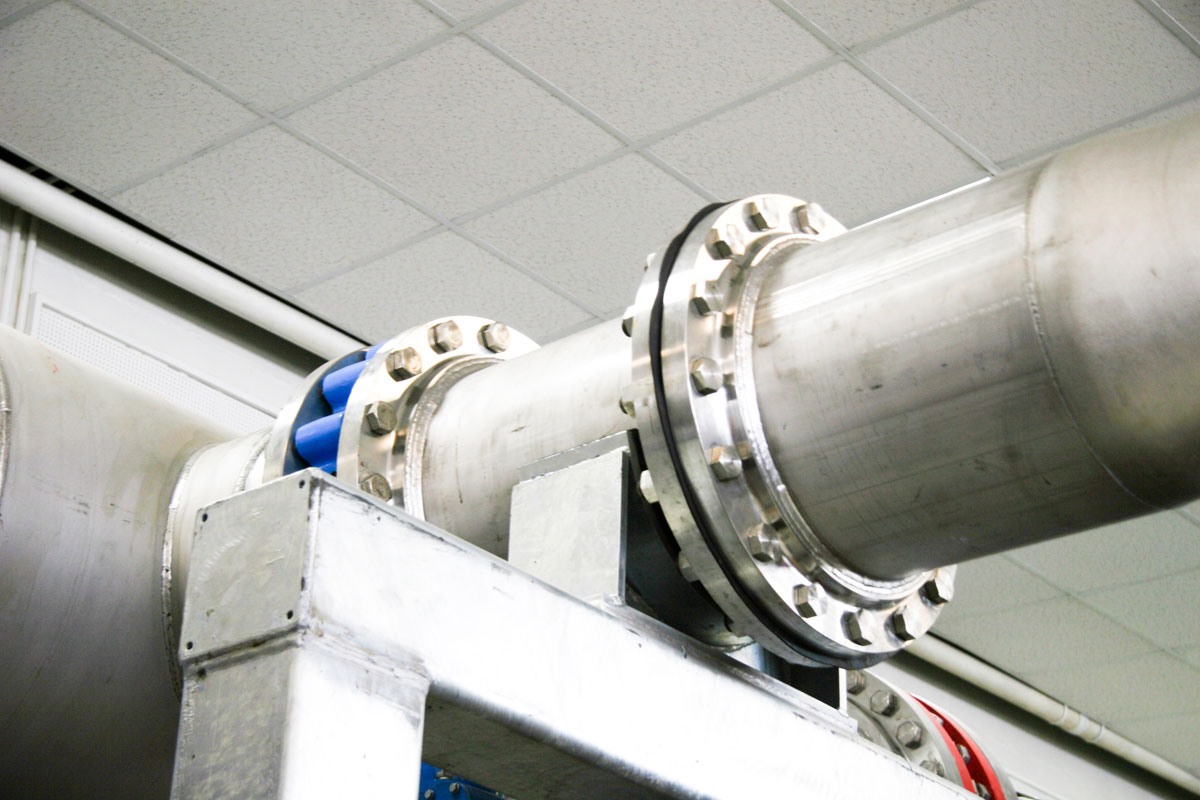

Ayr Welding delivers high quality stainless steel, carbon steel and exotic alloy piping systems. In business for over 45 years, our full-service approach begins with a dedicated project manager and in house designers to take your concept or requirement and make it a reality, while keeping a sharp eye on cost and constructability.

We have a great team dedicated to creating new deigns for new projects and bring many years of experience and problem solving to the table. In addition, we are well versed in optimizing and executing existing designs and ensuring adherence to requirements such as TSSA (technical Safety and Standards Association), ASTM (American Society of Testing and Materials), ASME (American Society of Mechanical Engineers), NSF (National Sanitization Foundation), and CSA (Canadian Standards Association).

The majority of the work we perform is dedicated to infrastructure, food, beverage, institutional, organics waste, and multi-residential facilities. We offer a wide range of piping sizes and thicknesses, including very custom requirements. Range includes (but is not limited to) sizes from 13mm to 3000mm diameter with thickness from light gages to schedule 160 pipe. Grooving Range includes sizes 50mm to 1500mm in many materials such as carbon steel, stainless steel (using RX Rolls), PVC, and aluminum.

We pride ourselves on a high attention to detail and quality service. Included in our process, every weld is visually inspected and reviewed to ensure customer requirements and codes are met before any project leaves our facility. We also offer a variety of in house or third-party testing including (but not limited to) pressure testing, radiography, magnetic particle and liquid penetration inspection.

Upon completion, all fabricated parts, spools and assemblies are cleaned and we offer a wide range of additional coatings depending on needs or requirements. Coatings include passivation, painting, powder coating, epoxy coating etc. We can ship our projects locally or worldwide and have great working relationships with many shipping vendors.

For more information or questions regarding prospective contracts or past projects please contact the Piping Division manager at [email protected] or call 519-580-7204.

OUR Plumbers & Pipe fitters WORK TO:

Review codes, prepare plans, adhere to project specifications, and rely on best practices to guarantee the best possible solutions

Are safe, reliable, responsible, and dependable

Show meticulous attention to detail to ensure the highest quality workmanship

Abide by rigorous quality control protocols to ensure specifications are met

OUR Piping SERVICES INCLUDE:

Construct, modify, repair, and remove piping systems

Threaded, welded, or mechanical joinings

Design, installation, and maintenance of multiple process piping systems, including glycol, thermal oil, steam, and condensate piping

Pneumatic and hydraulic piping systems and controls

Boiler and pressure vessel installations

Stainless steel fabrication

Installation and modification of systems equipment. This includes pumps, augers, grinders, compressors, valves, blowers, gates and more

Piping systems that meet the regulatory requirements for NSF/ANSI/CAN 61 – drinking water system components